SEAWATER DESALINATION

Seawater Desalination

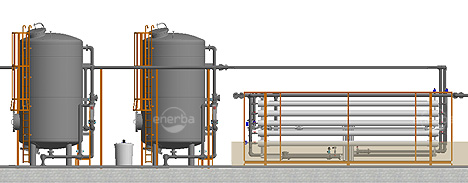

Designed to convert seawater to potable water, desalination systems use high quality reverse osmosis seawater membranes. The process separates dissolved salts by only allowing pure water to pass through the membrane fabric. PT. ENERBA TEKNOLOGI Seawater Reverse Osmosis (SWRO) systems are capable of removing salts as well as other impurities such as bacteria, sugars, proteins, dyes and constituents that have molecular weight greater than 150 – 250 Daltons.

SYSTEM CAPABILITY

PT. ENERBA TEKNOLOGI’s desalination systems are designed to provide high-throughput water production with minimum power consumption. These efficient models have capacities ranging from 200 to 1,500 m³/day. Larger systems can be custom-designed and manufactured.

SYSTEM KEY FEATURE

Pre-treatment (protecting the RO membranes)

High Pressure Pump

Energy Recovery Device

RO Membrane Modules

Clean-In-Place & Flushing System

PLC with remote monitoring or your operation at each site.

ENERGY RECOVERY DEVICE

In SWRO desalination industries, reducing energy consumption is one of the major areas of interest. The energy cost in the SWRO process typically accounts for about 30–50% of the total water production cost and can be as high as 75% of the operating cost, depending on the cost of electricity. Energy is therefore a major cost factor in the production of drinking water. Hence, reducing energy costs—mainly due to energy wasted in high-pressure brine—should be a primary goal for desalination industries.

ENERBA Seawater Reverse Osmosis

ENERBA Seawater Reverse Osmosis offers a reverse osmosis water treatment package designed to remove salts and other constituents such as bacteria, sugars, proteins, dyestuffs, and any components with a molecular weight greater than 150–250 Daltons. The high-pressure pump configuration of ENERBA SWRO is calculated based on your water salinity and typically ranges from 55 to 65 bar.

ENERBA Seawater Reverse Osmosis

Enerba designs and offers ready-made packages that are easy to operate for non-industrial applications. The core desalination process is reverse osmosis, in which semi-permeable membranes are used to separate salt water from fresh water.

OUR REFERENCE

Reverse osmosis (RO) has proven to be the most reliable, cost-effective, and energy-efficient method for producing fresh water compared to other desalination technologies. In 2017, Enerba successfully commissioned the desalination plant at PT Smelting, Gresik Smelter & Refinery.